Beyond the standard sensor types used in machine automation—such as photo eyes, limit switches and DC proximity sensors—are a wide range of color, contrast, AC proximity and area sensors. All of these sensors, as well as optical rotary encoders, are used to enable sorting, detection, error checking and positioning for machine automation.

Overview of Magnetic Proximity Sensors Magnetic proximity sensors are used for non-contact position detection beyond the normal limits of inductive sensors. In conjunction with a separate “damping” magnet, magnetic sensors offer very long sensing ranges from a small package size and can detect magnets through walls of non-ferrous metal, stainless steel, aluminum, plastic or wood. Depending on the orientation of the magnetic field the…

When it comes to detecting position and presence in automated equipment, be sure to consider limit switch as choices available today are robust, and can provide high precision. While photo eyes and inductive switches are popular choices in many applications, precision limit switches can be a better option with repeatable accuracy less than a micron.

AutomationDirect now offers Datalogic print mark contrast sensors with 6-12mm sensing distances. We also now offer the Contrinex DW-series of extended and triple-distance proximity sensors in 3mm to 30mm cylindrical and 20mm rectangular styles.

+Tech TopicsAutomation NotebookDiscrete SensingIssue 37 - 2017Learning ResourcesNotebook IssueProduct

How to Specify Fiber Optic Sensors

Fiber optic sensors work well in tight spots and in applications with a high degree of electrical noise, but care must be taken when specifying these critical components.

ApplicationApplication StoriesAutomation NotebookAutomationDirect SpotlightDiscrete SensingEducation/DIYIndustryIssue 37 - 2017Learning ResourcesMotion ControlNotebook IssuePLCProductProgrammable ControlStudent SpotlightTest and MeasurementVariable Speed Drives

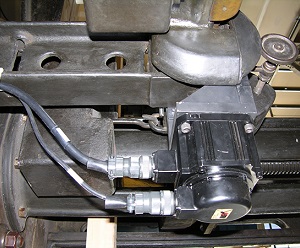

Beam Testing at Portland State

For their undergraduate senior capstone project, a team of Mechanical Engineering students at Portland State University (PSU) recently designed an electronic system upgrade for the control system of a 100-year-old beam testing machine. Using a range of AutomationDirect parts, the purpose of the project was to make the operator experience comparable to modern machines.

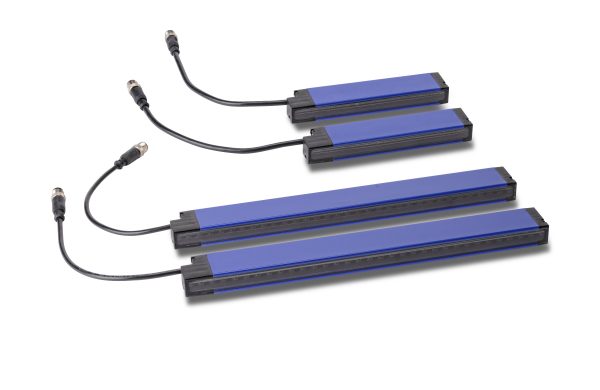

Part presence sensing is a critical part of automation. A controller must often sense a part is present in a fixture, or sense the part position on a conveyor, to make logic decisions such as run, stop, etc. Presence sensor types include photoelectric, inductive, capacitive and others—and this abundance of choices can complicate specifying the…

Object detection is sensing if an object is in proximity or not – that’s it, you get an ON or an OFF signal. A more advanced object detection function involves measuring the actual distance of an object from the sensing point. Ultrasonic sensors and laser distance sensors are commonly used to measure how far away…

A common function of a control system is detecting the presence of an object. Whether you are detecting the presence of an object passing by on a conveyor, the closure of a gate or the position of a machine part as it goes through its motions, object detection is a staple of the automation industry. There are…

+Tech TopicsDiscrete SensingeBookLearning ResourcesMotorsOnline OnlyPLC eBookProcess Sensing & ControlProductProgrammable Control

Ladder Logic in Action

Ladder logic programming for industrial controllers has evolved significantly over the years, and now supports advanced functionality such as process control, motion control, data manipulation, networking, and data acquisition. However, when you start with a blank page to design a new control system, large or small, there are many basic functions this tried-and-true language is…