Because AC motors are essential workhorses for industry, designers need to understand their applications to make detailed selections, such as single-phase or three-phase styles. Electric motors are a fundamental force for creating powered motion in any type of equipment. Initially developed in the 1800’s and refined significantly over the years, electric motors are now available…

DC motors provide a flexible and effective motive force for many machine and automation applications. Although direct current (DC) motor technology dates from the early 1800s, and other motor types have been developed since then, DC motors remain the best option for many applications. DC motors can be obtained in tiny consumer-grade form factors suitable…

ApplicationApplication StoriesIssue 49, 2023Machine ControlMotorsPLCProductProgrammable ControlVariable Speed Drives

Opening the Automation Door

A home project to upgrade a garage door system with an AutomationDirect PLC, HMI, and VFD made the equipment run better, added many functional features, and provided extensive visibility and diagnostics. Industrial automation components have many applications outside the factory. Home and hobbyist projects can be a great way for learning how to execute larger…

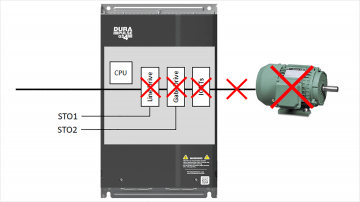

The safe torque off function built-in to modern VFDs significantly improves the integration of emergency stops. Kevin Kakascik, Technical Marketing Engineer with AutomationDirect, wrote an article for the May-June 2021 issue of Industrial Equipment News. The article, titled Motor Drive Safe Torque Off Improves Equipment Safety, explains the capability and how to use it. Here’s…

Stepper motors can be the best option, even for precision motion control applications, while avoiding the expense and complexity of servo motors. Standard AC induction and DC motors can only produce basic motion control, and servo motor solutions provide exceptional performance but drive up costs and complexity. For many motion control applications, stepper motor solutions…

New electric motors with multiple ratings simplify selection and use. Bryan Sisler, Product Manager for Drives and Motors at AutomationDirect, wrote an article for the February 2020 issue of Machine Design titled Newer Motor Designs Combine Functionality. Here’s a summary, click on the link above for the full text. A “one-size-fits-all” approach might be acceptable…

Proper motor sizing precludes equipment failures, ensures efficiency and reduces maintenance issues Bryan Sisler, a product manager for drives and motors at AutomationDirect, authored an article for the August 2019 issue of Plant Engineering titled Three Steps to Size Motors. Following is a summary, please click on the link above for the full text. Electric…

ApplicationApplication StoriesDrivesHMIIndustryIssue 42 - 2019Machine ControlManufacturingMotorsNotebook IssueOperator InterfacePLCProcess ControlProductProgrammable ControlVariable Speed Drives

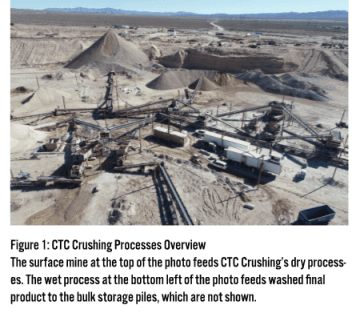

Crushing the Control System

Upgrading to a modern control system platform with the help of a local system integrator transforms a rock crushing plant from manual to fully automatic operation. By Todd Timpa, Assistant General Manager at CTC Crushing Impact Sand and Gravel is the leading supplier of aggregate and sand in the Las Vegas area, producing and distributing…

This AC motor and drive information will aid in selection and application. Jeff Payne, product manager for the drives & motors group at AutomationDirect, wrote an article for the January 2019 edition of Plant Service magazine titled Get schooled: AC motor basics Here’s a summary, click on the link above for the full text. Payne…

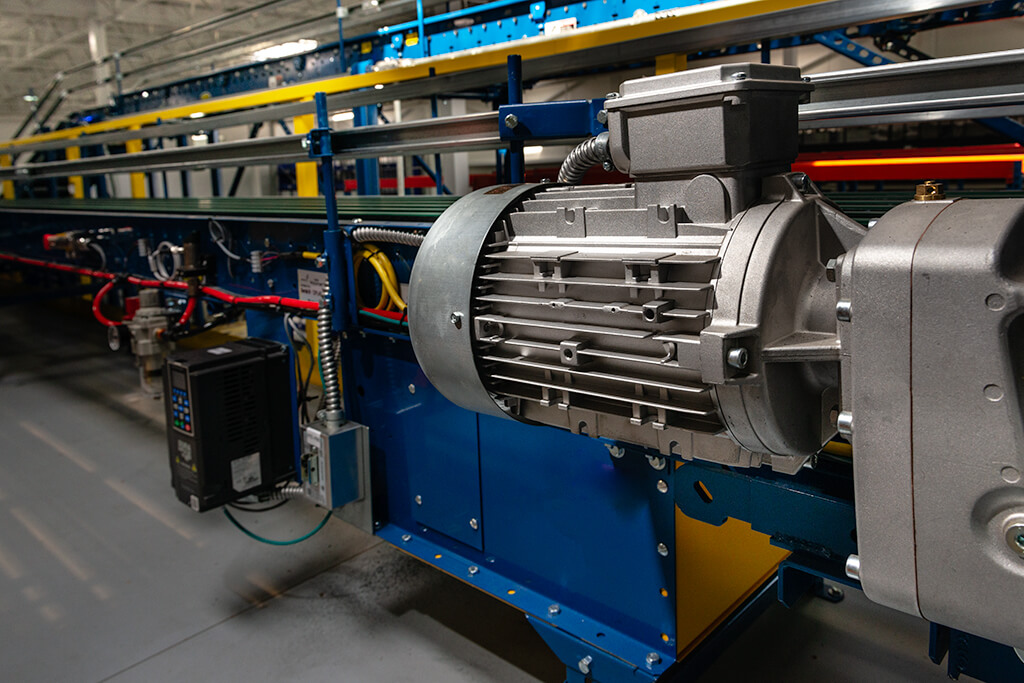

Most automatic controls involve AC motor control in some way, especially in factory automation. Applications such as pumps, fans, robotics, and conveyors use motors. Whether general-purpose 3-phase ac motors, which are great for simple on/off systems, or the inverter-duty motors specifically designed for operation with variable frequency drives (VFDs), one could say that motors are ubiquitous…