For determining the precise motion of industrial machinery and equipment elements, or servo motors, encoders provide a high-performance solution—but only if they are specified properly. By Joe Kimbrell, AutomationDirect Mechanical movement generated on automated machinery and equipment almost always needs to be monitored by sensors to provide a robust motion control solution. This is especially…

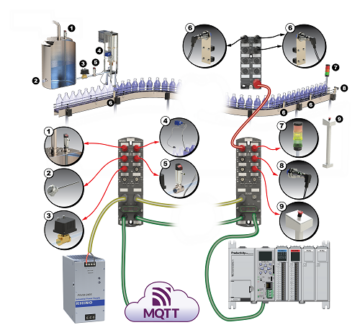

Smarter sensors and practical digital networking make premium automation capabilities accessible for discrete manufacturing applications. Large food and chemical production plants are typically called “process” operations, while machinery and equipment are considered “discrete” manufacturing, but both categories need effective detection and measurement technologies. Some technologies, such as smart sensors and digital fieldbuses have largely been…

There are many practical and cost-effective ways for designers to incorporate automation redundancy for systems of any size. Automation redundancy has largely been reserved for larger process automation systems due to cost and complexity. However, there are now more products and design strategies suitable for applying redundancy to smaller-scale systems. Rin Irvin at AutomationDirect covers…

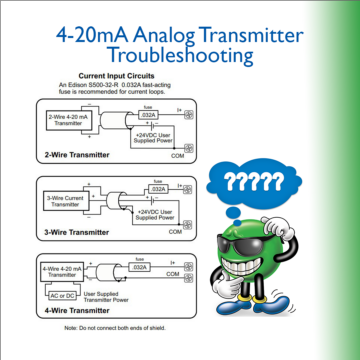

The 4-20mA analog current loop is a workhorse of automation, but initial setup and troubleshooting can be challenging, here are some tips to help. For all types of industrial machinery and automation, a basic 4 to 20 milliamp (4-20mA) wiring scheme has been one of the most prominent installation methods for transmitting analog signals. Digital…

Smart vision sensors incorporate on-board machine learning, empowering users to deploy them in common applications, without the cost and complexity of traditional products. Common photoelectric (PE) sensors are the most basic type of “vision” device, but traditionally it has required much more advanced technology to capture and analyze actual images for advanced detection. In an…

It happens more often than we’d like in the material handling industry. During an accumulation conveyor start-up, the photoelectric sensors cannot detect the totes that the conveyor transports. Even worse is when a conveyor system that has worked fine for a long time is suddenly unable to detect new totes introduced into the system. In…

When choosing a photoelectric sensor for an application there are many things to consider. One of these considerations is whether to select a light-operate or dark-operate photoelectric sensor. The terms “light-operate” and “dark-operate” refer to when the sensor activates its output. For a light-operate sensor (also called light-activated, light-on, or simply L.O. sensor), the output…

Using thermocouple sensors to measure temperatures in industrial applications. Thermocouple Definition Temperature measurement is one of the most common requirements for any industrial automation or digitally-monitored system. It is often necessary to detect the temperature of gases, liquids, and physical equipment components. The primary contact-based technologies for doing so are thermocouples (TCs), resistance temperature detectors…

+Tech TopicsDiscrete SensingLearning ResourcesProcess Sensing & ControlProductProgrammable ControlSensors Automation

Basic Sensors - PLC Fundamentals

For a PLC to monitor and in turn control its application variables, there must be a way for it to sense its surroundings. In today’s industrial realm, there are a huge variety of electrical sensors that provide the input data (position, distance, level, flow, etc.) that control systems need. These basic sensors can be broken…

A variety of analog signals must be transmitted to a PLC for monitoring and control, with each processed to ensure correct operation. Winn Paulk, the Automation Controls Group Product Manager at AutomationDirect, wrote an article for the November 2018 issue of Processing magazine titled Configuring analog devices to integrate with PLCs. All programmable logic controllers…