AutomationDirect’s BRX PLC brings new world capabilities to old world machines.

David Adams founded Design Automated Controls (DAC) in Alabama to support clients with design/build capabilities and onsite service, and he has had great success using AutomationDirect PLCs and products.

In an April 2022 Tech Briefs article bylined by David, titled Ginning Up a Modern Automation Platform, he describes how a modern BRX PLC enabled him to efficiently automate a cotton gin and provide the best possible value for his client.

Cotton gins—the term “gin” is a contraction of “engine”—were invented over 200 years ago to separate the useful fibers from the seeds, but today’s versions benefit from modern automation.

Considering Control Options

Like other machines and production equipment, cotton gins use motors, solenoids, hydraulics, and other mechanisms. These operations are seasonal, and the equipment runs round the clock at times so it must be reliable.

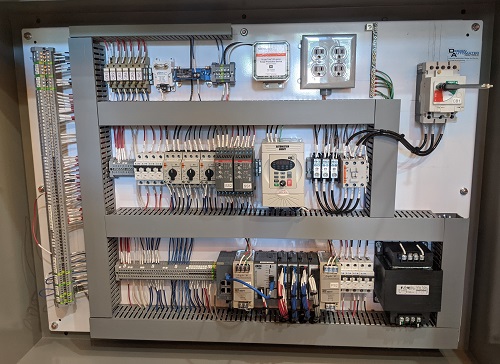

When a client came to DAC with a fast-track cotton gin automation retrofit project which had to be completed before the harvest started, it knew right where to start. DAC had plenty of previous experience with AutomationDirect products, and recognized that the wide variety of options, dependable support, easy programming, and ready product availability would work well for this project. DAC rapidly designed a control panel using AutomationDirect parts like a BRX Series PLC, GS2 Series VFD, and other instruments and components.

Key Features Drive Selection

Some key BRX features led DAC to choose this PLC over other options:

- Native MODBUS/TCP communications

- Analog I/O with built-in configuration and scaling

- Pluggable option module (POM) as a flexible way to add an additional communication port

- Embedded IIoT support

- Free and easy configuration software

- Immediate product availability

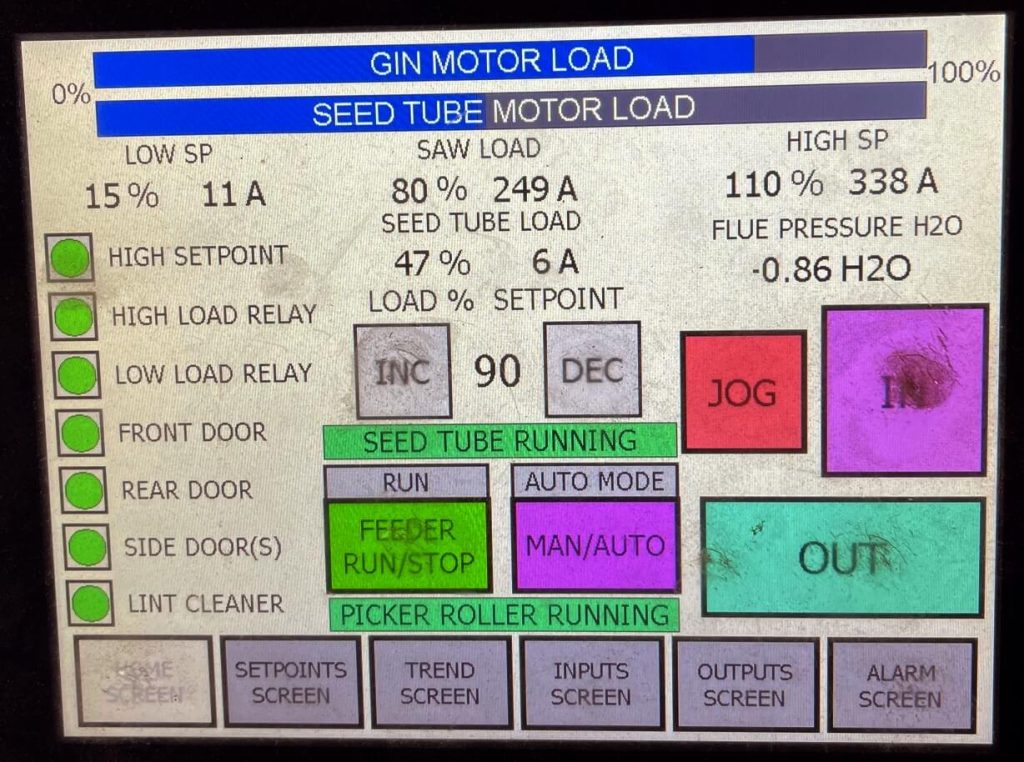

The BRX programming was easy to learn, and it worked smoothly with the CIMON HMI specified for the project, providing [DH1] users with a clear and simple interface matching their standards.

The initial project scope was for basic functionality, and DAC took advantage of remote support capabilities to assist with the smooth startup. Future work will likely include additional remote and IIoT capabilities, which the BRX will support. For this project and many others, DAC is an enthusiastic user of AutomationDirect products.

The BRX Series of PLCs meets these and other needs by delivering traditional PLC reliability in a compact form factor, with options for built-in and expandable I/O, and modern communication capabilities.

All figures courtesy of Design Automated Controls