Improved technologies and expanded user demands have pushed the evolution of industrial automation technologies, and PLCs continue to advance and meet these needs. Almost a decade ago, Jeff Payne at AutomationDirect wrote a Control Engineering article titled Future of the PLC . At that time, PLC technology was already 50 years mature but still a…

This electrical contractor relied on AutomationDirect PLC and HMI hardware and software to rapidly rip-and-replace the controls on a failing rock crusher. Equipment used in rock quarrying operations is subjected to extremes of dirt, vibration, heat, and more, pressing mechanical and electrical systems to the limit. When the crushing equipment legacy automation at one site…

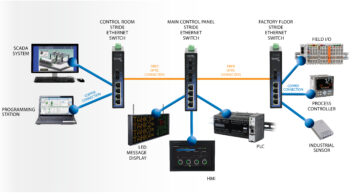

Once only suitable for sheltered office installations, Ethernet media and protocols can now efficiently serve and future-proof a variety of industrial applications. Once upon a time (think 1980s), Ethernet was a relatively specialized computer connectivity technology, administrated by experienced gurus under highly-controlled office settings. Since then, technology and performance have advanced incredibly, and much of…

Solar thermal installations need advanced control systems to optimize energy harvesting, storage, and distribution at remote mining operations. For certain applications in the right geographic areas, solar thermal can be a cost effective and low carbon way to supply large-scale heat energy. Flemming Jørgensen, of Jorgensen Thermal solutions, supplies these systems, and he needed to…

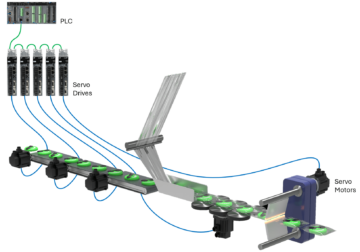

Modern multi-axis servo systems require a network for coordination of all the various movements. EtherCAT provides a high-speed cyclic mode that can update all the servo systems on the network within a few milliseconds. EtherCAT multi-axis servo systems can be created using the LS Electric XGB PLC in conjunction with LS Electric iX7 servo systems…

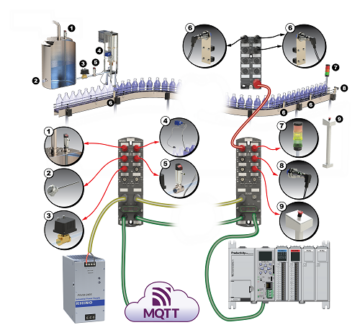

Electro-pneumatic I/O and solenoid systems save control panel space while simplifying installation and maintenance. Machine builders and OEMs everywhere are striving to meet customer demands to deliver smarter, more modular, and physically compact systems—often requiring more instrumentation and control points. In a Fluid Power World January/February 2024 article titled Distributed Electro-Pneumatics Streamline Equipment Designs, AutomationDirect’s…

Smarter sensors and practical digital networking make premium automation capabilities accessible for discrete manufacturing applications. Large food and chemical production plants are typically called “process” operations, while machinery and equipment are considered “discrete” manufacturing, but both categories need effective detection and measurement technologies. Some technologies, such as smart sensors and digital fieldbuses have largely been…

EtherCAT, which stands for Ethernet for Control Automation Technology, is a high-performance industrial network protocol based on standard Ethernet. It’s specifically designed for real-time communication and deterministic data exchange, making it ideal for motion control applications like robotics, assembly lines, and packaging machines. Key Features: Motion Control using EtherCAT: Benefits of using EtherCAT for Motion…

The Do-more BRX PLCs are very powerful controllers that utilize device-centric programming, allowing common functions to be configured as “devices” that run in the background without any ladder code and independent of the PLC scan. One such function is Modbus communication which, with the release of Do-more Designer 2.9.1, can be done via the new…

There are many practical and cost-effective ways for designers to incorporate automation redundancy for systems of any size. Automation redundancy has largely been reserved for larger process automation systems due to cost and complexity. However, there are now more products and design strategies suitable for applying redundancy to smaller-scale systems. Rin Irvin at AutomationDirect covers…