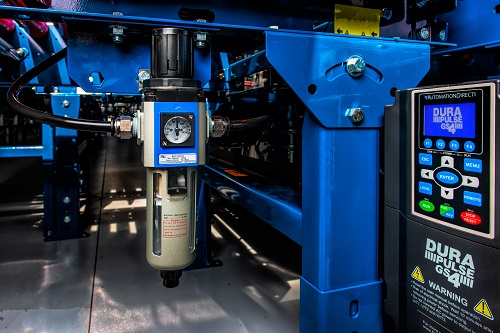

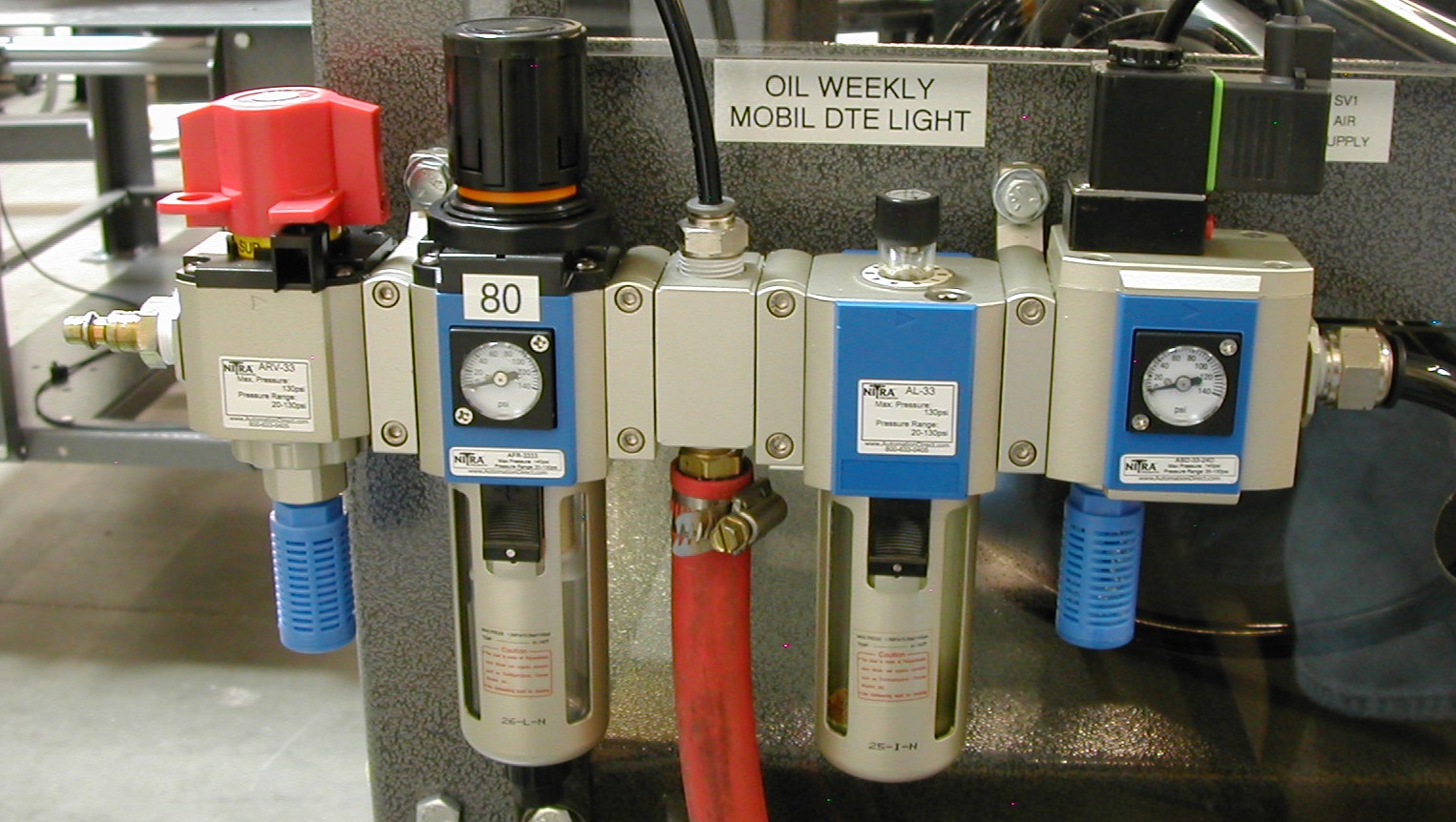

Available in many combinations, filters and regulators are a must-have on any machine. Other devices to perform functions such as energy isolation, lockout tagout and lubrication should also be considered. Chip McDaniel, technical marketer for AutomationDirect, wrote an article for the January 2019 issue of Design World magazine, titled Proper Air Preparation for Automated Machines….

In machine automation a pneumatic system provides a simple and cost-effective means to move, clamp, rotate, grind and screw. A pneumatic system is a collection of interconnected components using compressed air to do work for automated equipment. Examples can be found in industrial manufacturing, a home garage or a dentist office. This work is produced…

Here are some best practices to supply safe, clean and dry air to a machine or an item of equipment. Pat Phillips, Product Manager, Fluid Power & Mechanical Products at AutomationDirect, wrote an article for the October 2018 issue of Fluid Power World magazine titled What type of air prep is required for plant compressed air?…

Even with best efforts to supply clean and dry plant air, point-of-use air preparation is still needed for safe and reliable pneumatic machine operation. Pat Phillips, Product Manager, Fluid Power & Mechanical Products at AutomationDirect, wrote an article for the August 2018 issue of Industrial Equipment News titled Safely Provide Clean Air to Machines with…

Pneumatics have been used in industrial machines and manufacturing plants and facilities for decades, so most of the basic components are tried and true, with significant innovations few and far between. But there are many innovative ways to combine these different components to create pneumatic subsystems. The explains four pneumatic subsystems, showing how combining basic…

Chip McDaniel, Technical Marketing at AutomationDirect wrote an article titled Tubing versus Hose in Pneumatic Systems for the February 2018 issue of Fluid Power World. The article looked at some of the differences between tubing and hose, and related fittings—and at best practices for design, selection and implementation of each. Tubing and hose play a…

To control pneumatic cylinders and actuators with fluid power, air flow must be reliably controlled, typically with a solenoid valve. Pat Phillips, Product Manager, Fluid Power & Mechanical Products at AutomationDirect, wrote an article titled There’s a Valve for That, which ran in the November-December 2017 issue of IEN magazine. In the article, he discussed…

Just like electricity, natural gas and water, compressed air is often a required utility in manufacturing facilities. Although compressed air is a bit more expensive compared to electricity for industrial machinery applications, it has other advantages and is thus frequently used to drive mechanical motion. Simplicity of Pneumatics Chip McDaniel, Technical Marketing Engineer at AutomationDirect,…

A quick look online for control of fluid power shows many types of pneumatic valves for use in factory automation, most of them standalone and individually mounted. But there are also many valve manifold options, including compact modular valves, which are often the best option in multivalve applications because they simplify selection, installation, use and…

ApplicationApplication StoriesEducation/DIYEntertainmentHMIIndustryMachine ControlOnline OnlyOperator InterfacePLCPneumaticsPneumaticsProductProgrammable ControlVariable Speed Drives

The Halloween Box

In every haunted house, you’ll find automated props: chairs that rock on their own, slamming doors, rattling chains, drawers opening and closing as if by some supernatural force. These “tricks” enhance the “treat” of getting the life scared out of you. The process behind making a Halloween prop can be quite simple. Here is just…