AgricultureApplicationApplication StoriesData CollectionData System MonitoringIndustryMachine ControlOperator InterfacePLCProcess ControlProductProgrammable ControlWater/Wastewater

SCADA Upgrade Provides Quick Compliance

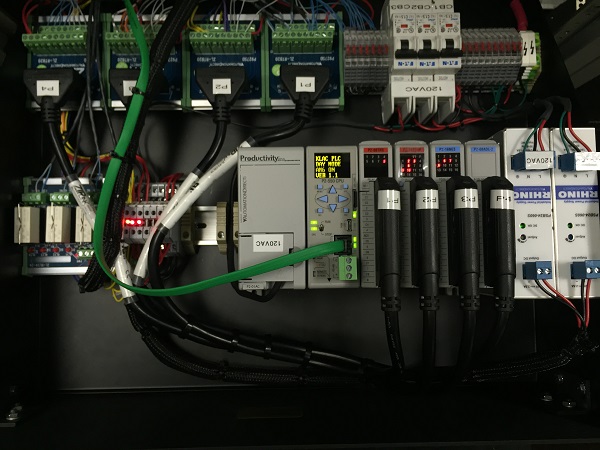

Sensible Automation Solutions updated its customer to an AutomationDirect BRX Do-more PLC to add needed capabilities and data reporting to an existing wastewater treatment system.