Intelligent HMI advances can justify upgrades based on significant improvements associated with ease-of-use, cybersecurity, and other advanced features. Consumers are accustomed to rapidly upgrading their personal electronic devices by buying new hardware and updating apps, but the industrial automation world usually works at a slower and more delayed pace in this regard. Greg Philbrook, HMI…

A truck customization shop expanded their capabilities by offering AutomationDirect PLCs and HMIs to control expansive on-vehicle lighting displays. Just as many car owners like to customize their rides, there is a growing convoy of truck operators who like to do the same as a personal and promotional statement. Dickerson Custom Trucks has been catering…

Human beings are visual creatures. It’s believed that our brains can process visual information 60,000 times faster than text, with 90 percent of information transmitted to the brain being visual and over half of the brain being devoted directly or indirectly to vision. Knowing that, it’s easy to see how a visualrepresentation of an automated…

ApplicationApplication StoriesFood and BeverageHMIIndustryIssue 51 2024Machine ControlOperator InterfacePLCProductProgrammable Control

In-House Automation Focuses on People, Plant, and Profit

A cheese manufacturer developed in-house automation capabilities to keep legacy equipment running and responsively adjust to production demands. Many companies rely on external firms for automation upgrades and changes, and this works well for countless applications. But Pacific Cheese Company faced a dual challenge of maintaining and improving manual and legacy systems, while at the…

CommunicationsData and IIoTData System MonitoringIssue 51 2024Operator InterfaceProgrammable Control

Modern PLCs Provide Support for Advanced Data Access

Although many think of PLCs as primarily for real-time control, modern versions make it easy to implement extensive data connectivity and analytics. While everyday consumers are familiar with getting things their way, this type of flexibility has often been less available within the industrial manufacturing arena. This is an issue for many end users when…

Manufacturers are finding they can rapidly and flexibly adapt to changing production needs by engaging in-house personnel to deploy automation solutions. Automation is essential for improving productivity and quality, but many manufacturers serve markets where production volumes and product options vary drastically. As a senior maintenance and integration supervisor at Keytronic, Jose Luis Rodriguez Persona…

This company is using modern PLCs and HMIs to revamp existing agricultural equipment automation systems, improving efficiency and adding advanced IIoT capabilities. Modern agriculture relies directly and indirectly on automated equipment for growing, processing, and transporting product. Vinny Endres grew up in a farming family and quickly learned how to keep things up and running….

Modern processing plants need control panels built in accordance with specific design details. Chris Kregoski, product engineer for AutomationDirect, authored an article for the July 2022 Processing magazine titled Process Control Panel Design Basics. Here’s a summary, click on the link above for the full text. Processing plants typically incorporate extensive automation. The control panels…

Using the AutomationDirect Do-more BRX PLC, an extrusion company progressively upgraded and simplified their legacy manufacturing lines, greatly improving performance, while minimizing scrap. The situation is common at many manufacturing sites: production equipment is old, degrading, and mismatched, leading to operational and maintenance inefficiencies and nightmares. In an April 2022 Automation.com article bylined by Gary…

ApplicationApplication StoriesIssue 48 -2022Notebook IssueOpen source controlOperator InterfacePLCProcess ControlProductProgrammable Control

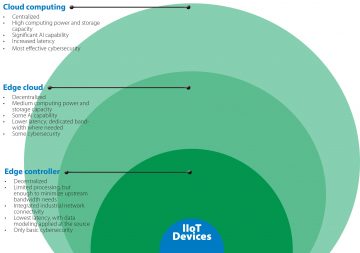

Connecting AI to the OT

This greenhouse automation startup shows how AutomationDirect controllers are a flexible platform for connecting cloud-based artificial intelligence to practical operations manufacturing automation. Connecting AI concepts to age-old agricultural operations using modern IoT methods is the ambitious undertaking of Kenneth Tran and his team at Koidra. The resulting “artificial intelligence of things” (AIoT) is yielding positive…